1 Time slots and delivery deadlines

Good timing is more important than ever. And this is one of the most common planning constraints along the supply chain. Since there are no more buffers, it is often no longer sufficient to specify a delivery date. Recipients prefer to be given an exact delivery time, or at least a specific time slot, so that they can set their own schedules accordingly. Not to mention the narrow time slots for inner-city deliveries, or the delivery times that must be booked in advance at the distribution centers. If you’re late, you lose.

2 Weights, volumes, and dimensions

From standard trailers to Super EcoCombis (duo trailers) with a total weight of up to 72 tons: The maximum permissible load volume in road freight transport is growing. But every cargo compartment has a limit. Therefore, it is important to have accurate data on the dimensions and weight of each piece of cargo, so that the cargo space can be used optimally. That one load that just fits can make the difference between one more truck and one less.

3 Qualification standards for drivers

All drivers have different skills. Some drivers have a license to haul hazardous materials, while others have a license to operate heavy truck combinations. Some do not speak English or can barely communicate in English. In addition, each driver has his or her own preferences. Some want to be home every night, while others prefer international multi-day trips. And sometimes it makes sense to send the same drivers to the same customers over and over again. A route planning system takes all these aspects into account.

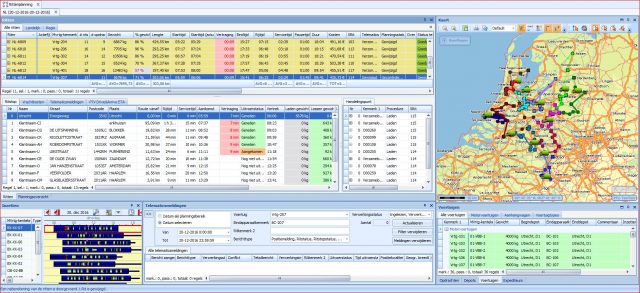

4 Multi-depot planning

Carriers often split the planning and create schedules for their international and domestic transportation operations. If the distribution network consists of several depots, each depot often has its own scheduling process. A route planning system allows different plans to be run in parallel. In this case, it is important to allocate the right transport order to the right dispatcher. Of course, there is also the possibility of re-allocating the transport orders, if necessary.

5 Vehicle profiles and vehicle specifications

Does the cargo consist of fresh produce that must be transported in a climate-controlled trailer? Or is it building materials that require a mobile lift truck? Or do the goods have to be delivered to a customer located in an emission-free zone? Various vehicle attributes can be defined in a route planning system: This way, the planner can be sure that the shipment will be transported by the most suitable truck.

Apart from that: The best route for a delivery truck usually differs from that of a trailer truck concerning travel times and distances. The right vehicle profile then helps to improve planning in terms of accuracy and reliability.

Want to find out more about route planning software?

Simply download the free eGuide.

6 Loading and unloading times

No two stopovers are the same. It makes a big difference whether drivers can stop directly in front of the store or only in a side road 50 meters away – and this regardless of whether they have to deliver one cardboard box or four roll containers. Planners who collect data on the time it takes drivers to load or unload goods can enter the average dwell time per address into a route planning system, so that they receive more accurate and reliable planning results, which also help reduce driver stress.

7 ETA calculation und communication

Customer agreements are an important element in improving customer service – for both the company and the customer. Agreements help build trust and improve service reliability. It is also helpful to communicate the Estimated Time of Arrival (ETA) and constantly provide the contractual partners with up-to-date information. Knowing the estimated time of arrival makes it easier for them to optimize their own schedules. If delays occur, arrival times can be tracked in real time and scheduled again by the recipient. Today’s customers expect to be notified of their parcel’s scheduled delivery date; being informed in real time is an additional benefit.

8 Deliveries and assemblies

It is often not enough to simply push a few boxes behind the door. Many companies offer additional services, such as delivery to the appropriate department, shelf replenishment, furniture assembly and installation of machinery. This requires suppliers with the right knowledge, skills, and tools. And sometimes two people are needed to move large and heavy goods to the right place.

9 Deliveries and returns

Combining pickup and delivery of shipments in one trip presents an additional challenge for dispatching. A fully loaded truck must first deliver enough goods before loading new items. A route planning system puts the stops in the right order so that drivers don’t have to fiddle with pallets and boxes in their trucks.

10 Driving times and rest periods

The fines for violations of the prescribed driving times and rest periods can amount to thousands of euros. A route planning system takes into account the driving times and rest periods of all drivers when creating a route proposal. This means that all generated tours adhere to the maximum limits. In addition, it is possible to optimally plan the legally required rest periods, for example at a time when the drivers have to wait during the scheduled tour.

These constraints are well explained apart from deliveries and assemblies and multi depot planning which I never understood, can I get more clarity sir?